Return Air Duct Size Chart

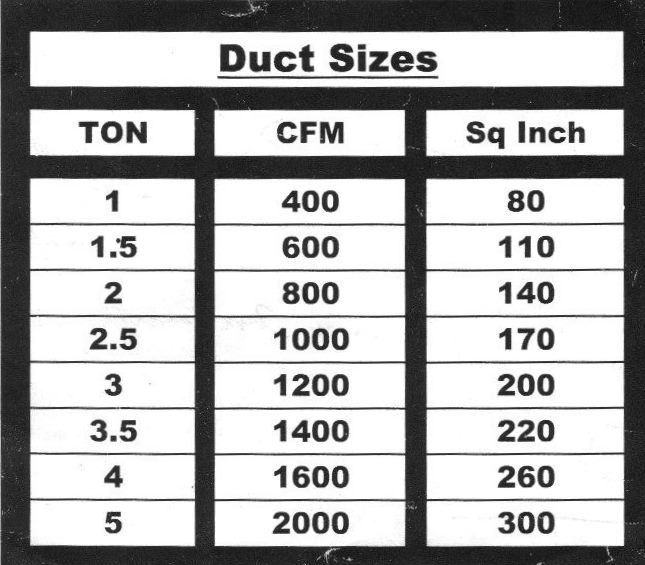

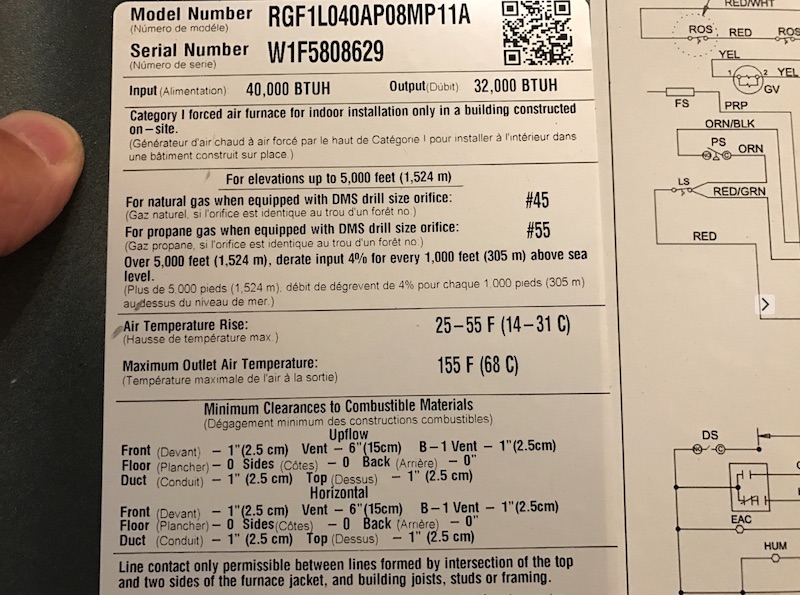

Our current duct work is 5 in we live in an older house probably only had heat at the time he wants to upgrade to 8 inch duct work upgrade to a 3 5 ton 13 ser increase the size of our return air thing and add a register to our large living room.

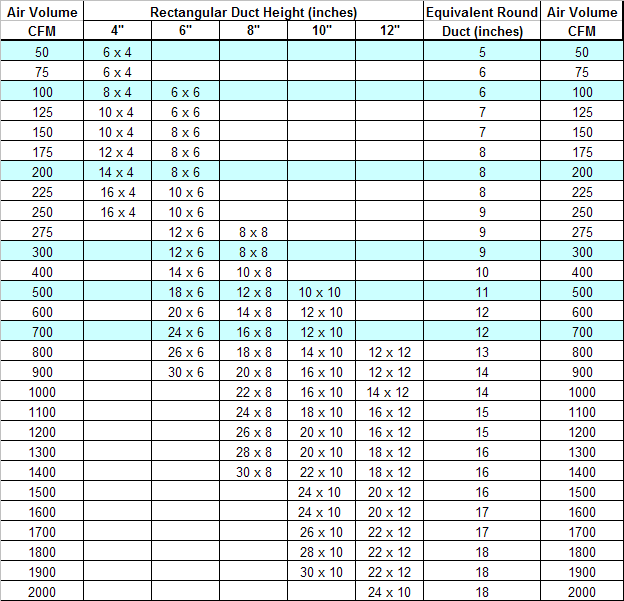

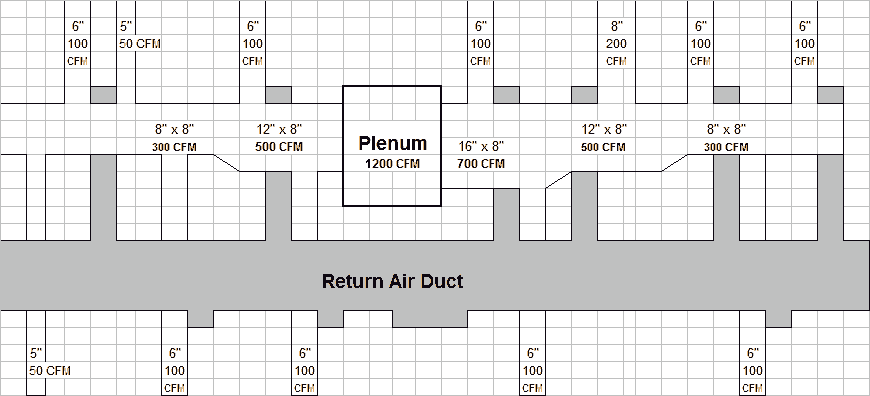

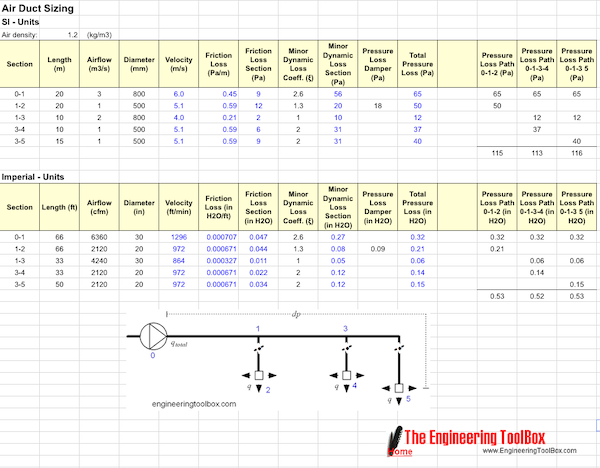

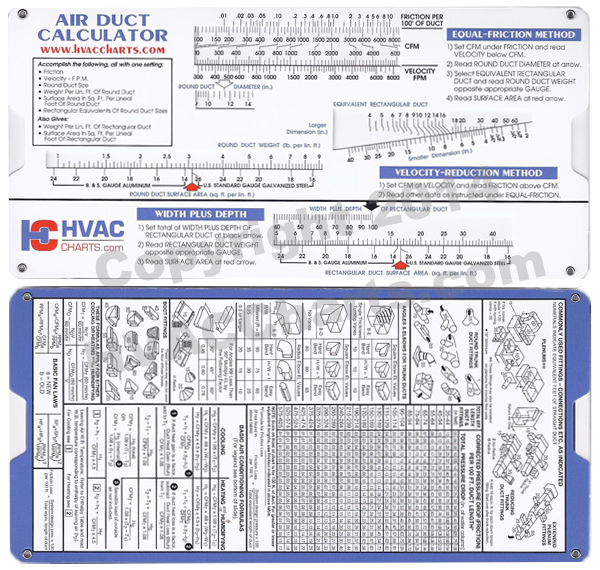

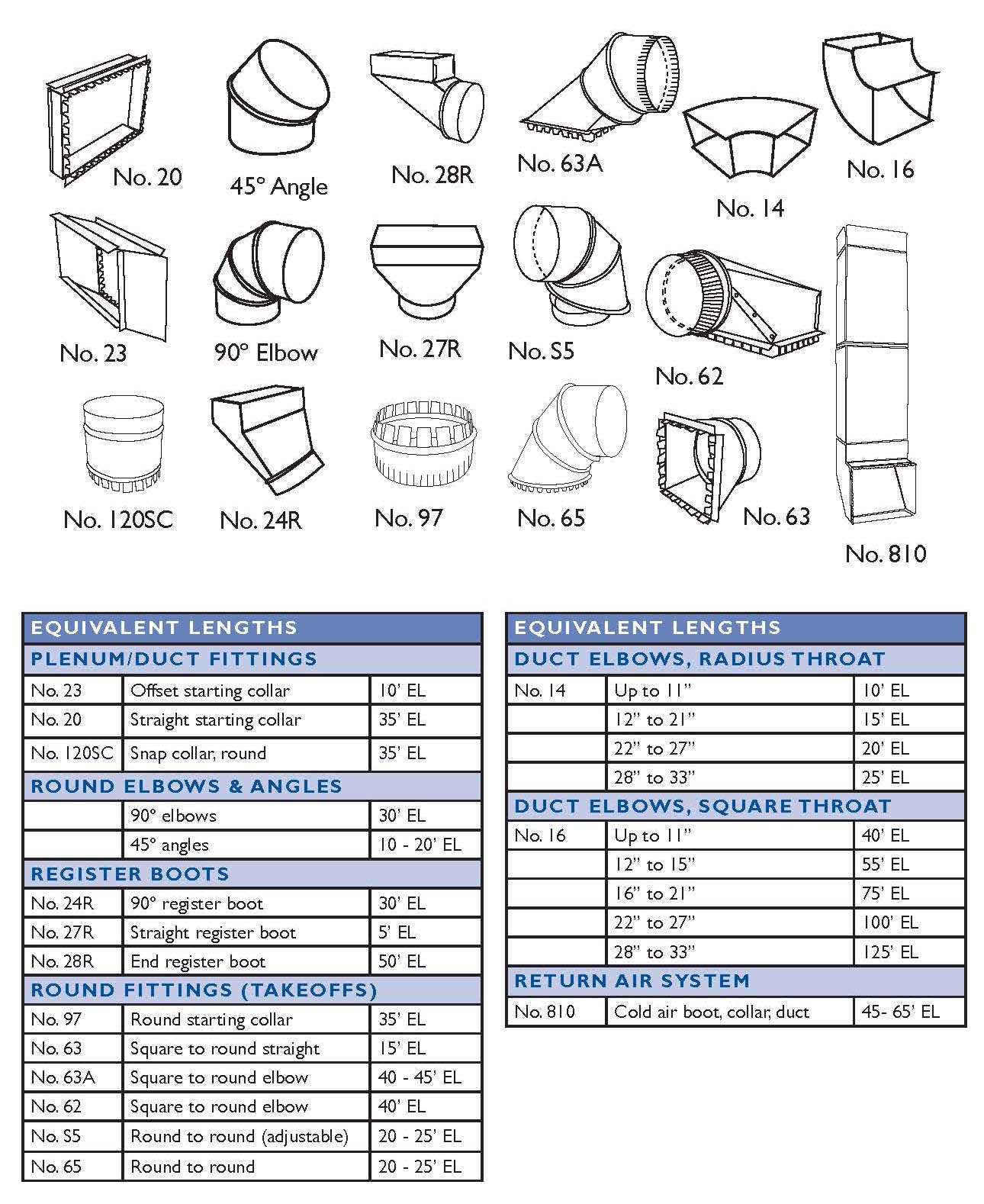

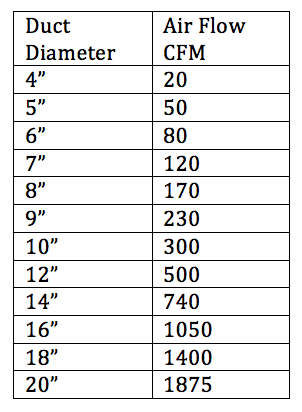

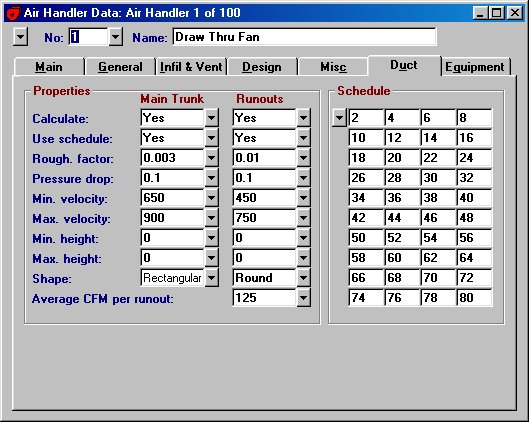

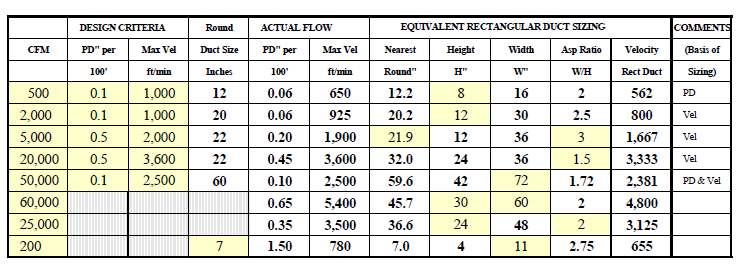

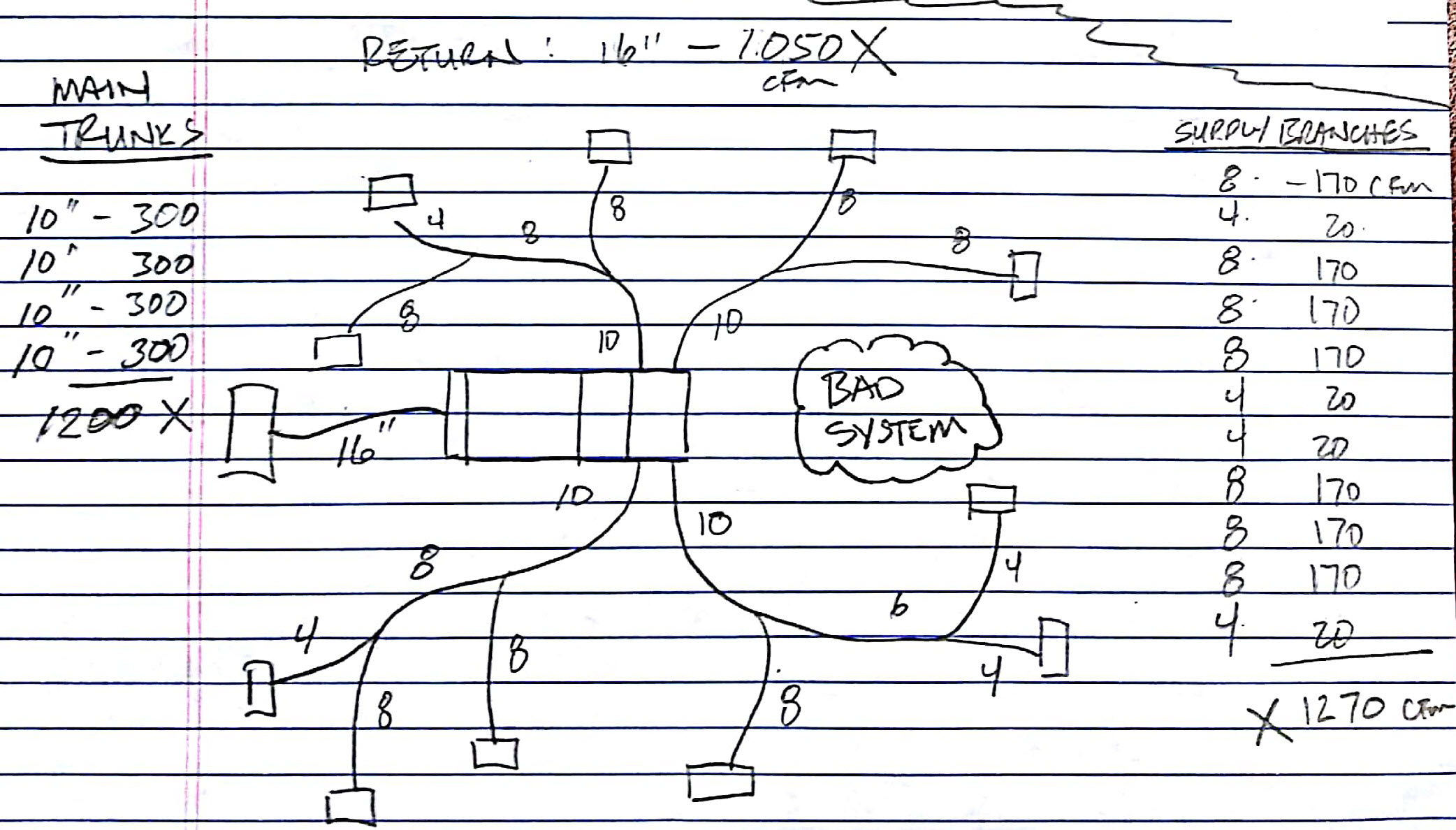

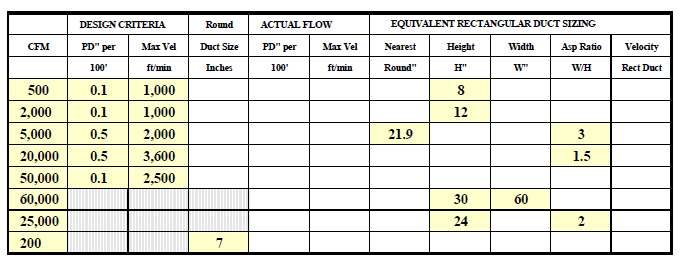

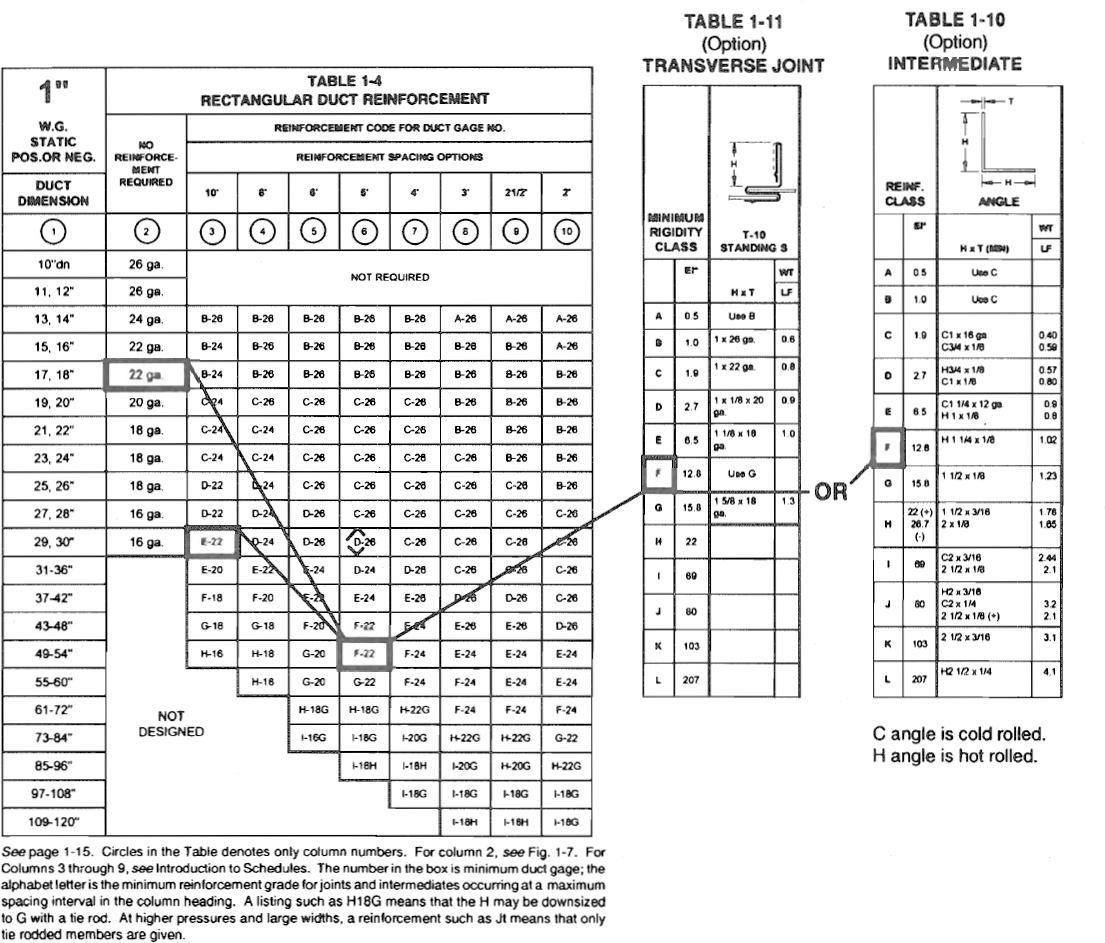

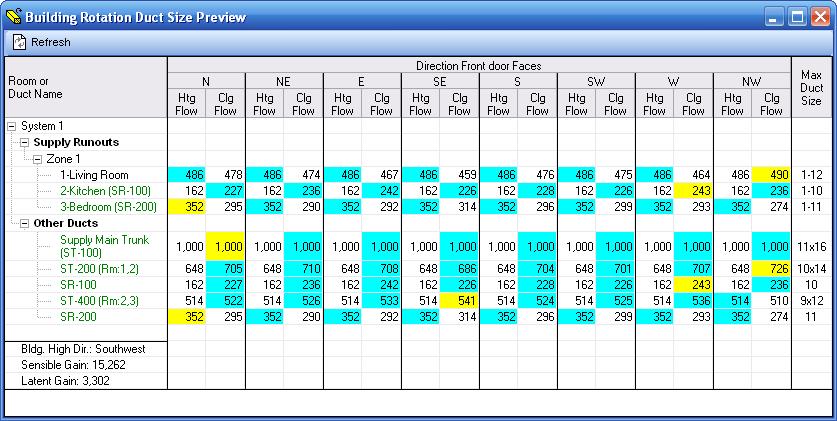

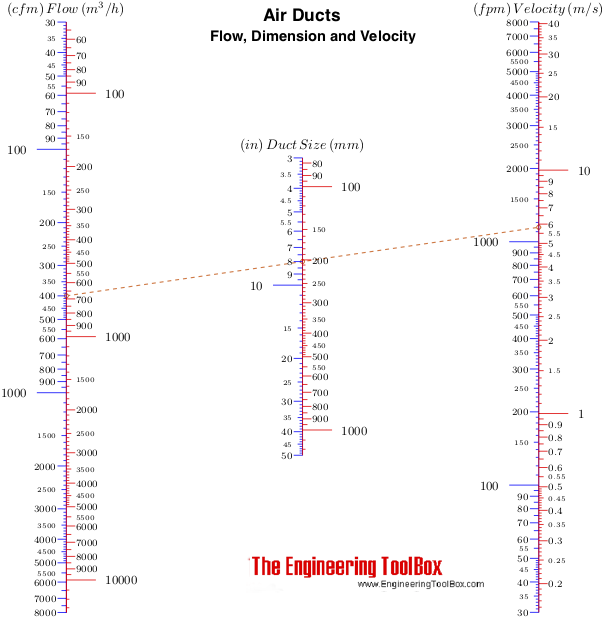

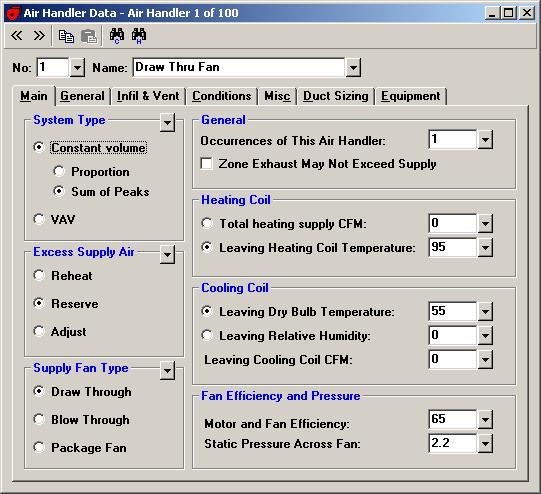

Return air duct size chart. In this instance the 800 cfm divided by 4 000 ft min calls for a duct area of 0 2 sq feet. Do not use data for round sheet metal duct. Tees split but do not reduce and an appropriate reducer must be added.

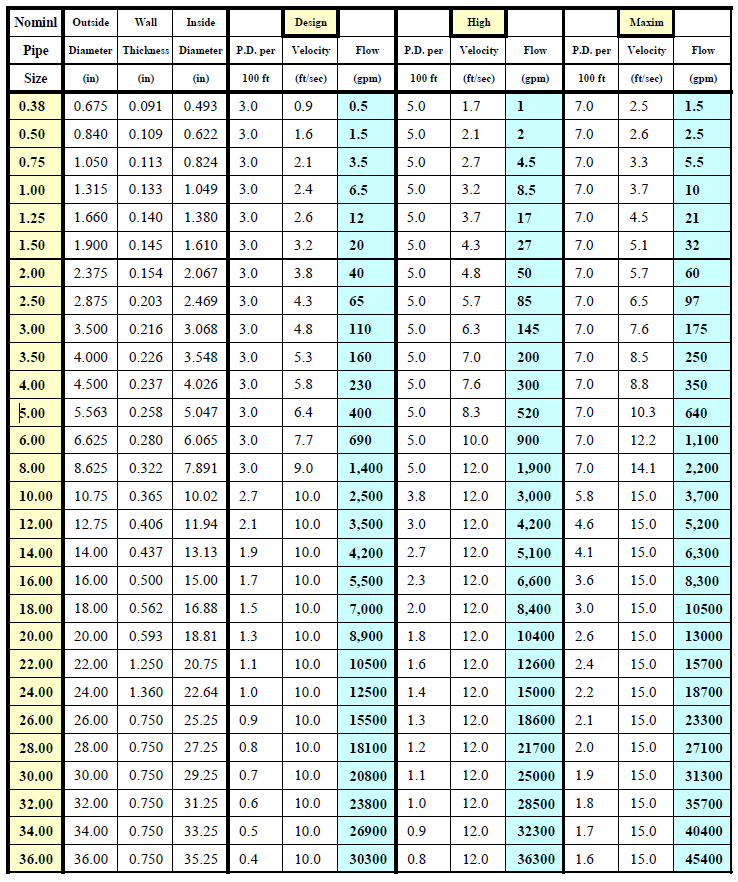

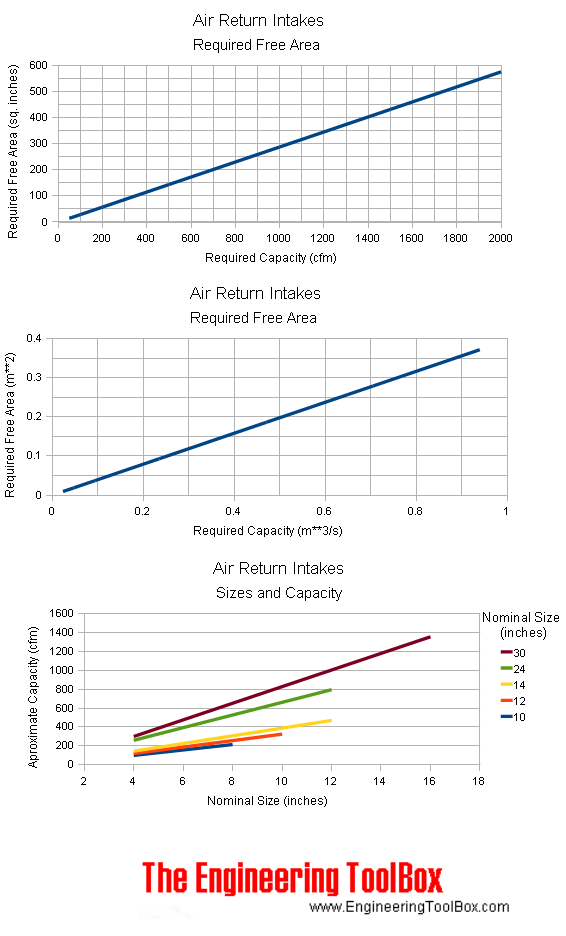

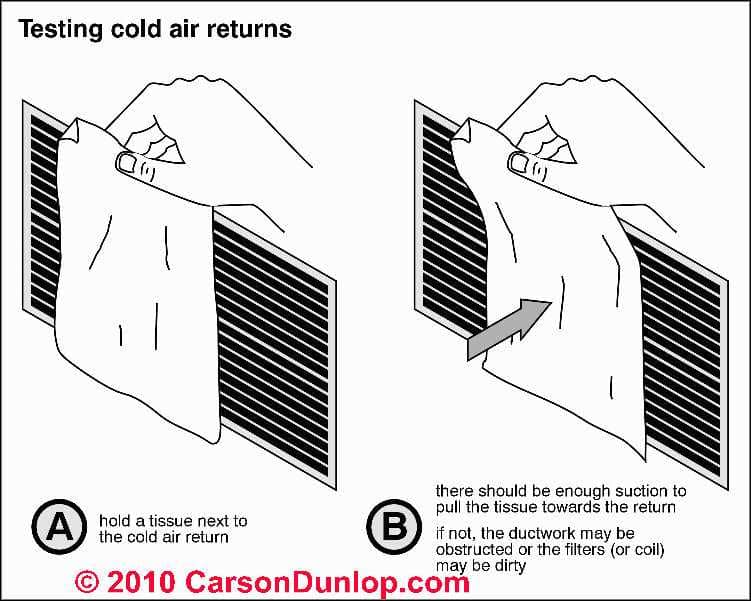

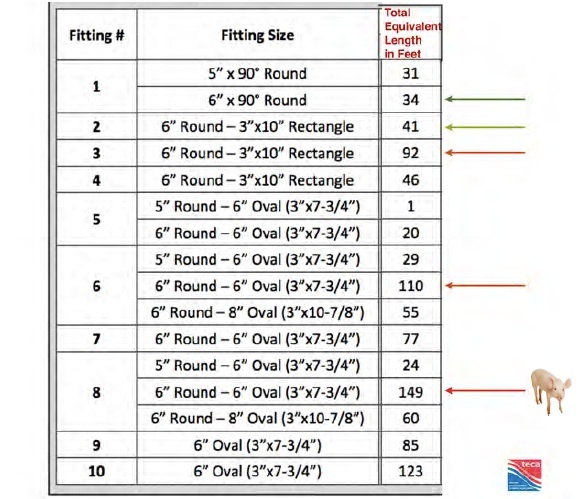

If clean air return duct is required duct resistance should also be calculated. Since the early 1970 s a significant increase in the use of flexible duct which generally is internally lined with plastic or some other type of material has occurred. For the same 2 5 ton system with a filter grille the grille size would need to be what size asked rick we usually use a 20 x 20 for 2 5 ton said the tech 20 x 20 x 2 800 800 cfm well that s big enough for a 2 ton but a 20 x 25 may be a better choice.

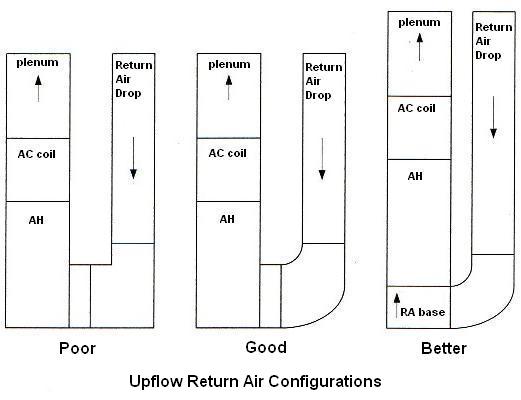

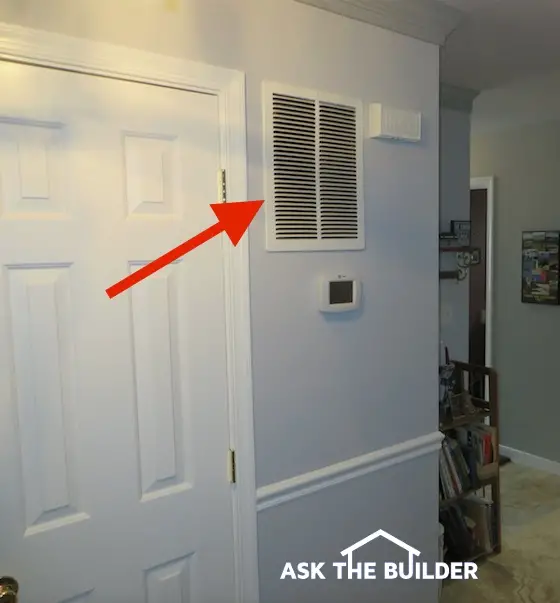

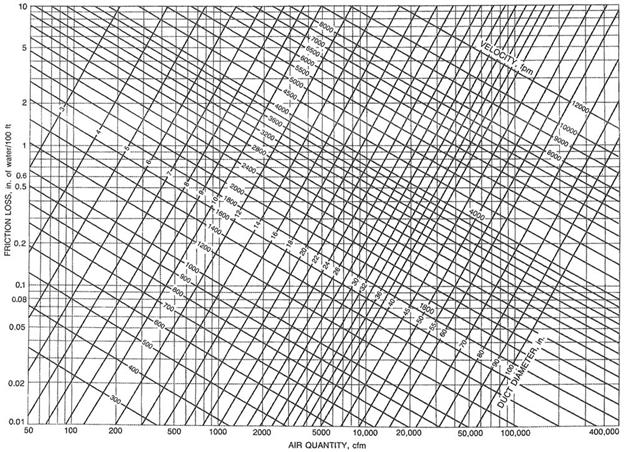

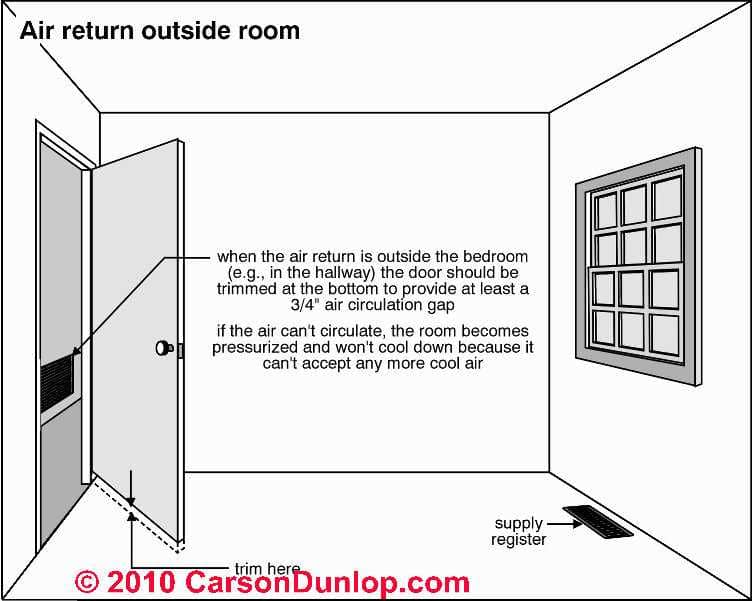

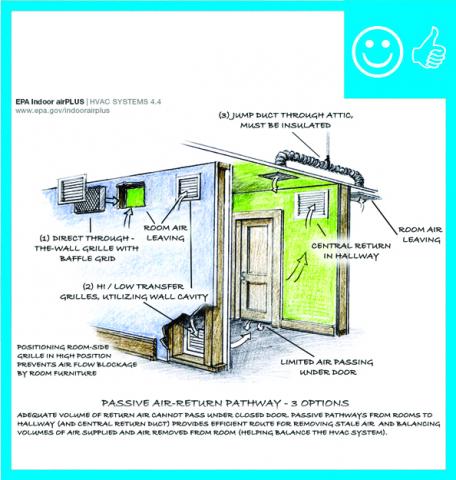

You have determined the velocity cfm static pressure and the size of the ductwork. Most people don t know that simply closing a door in their home can make them sick increase their energy bills or reduce their comfort. 0 2 sq ft x 144 sq in sq ft 28 8 sq inches cross sectional area of duct.

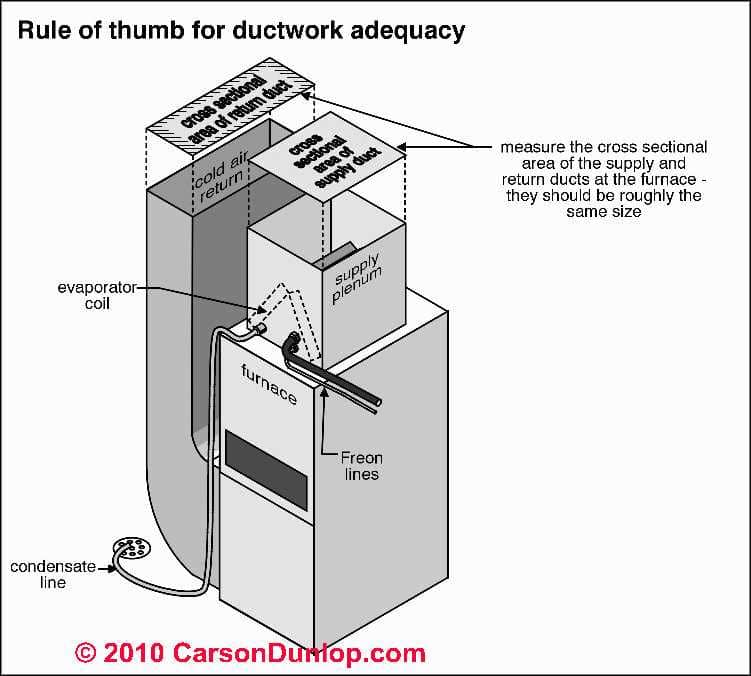

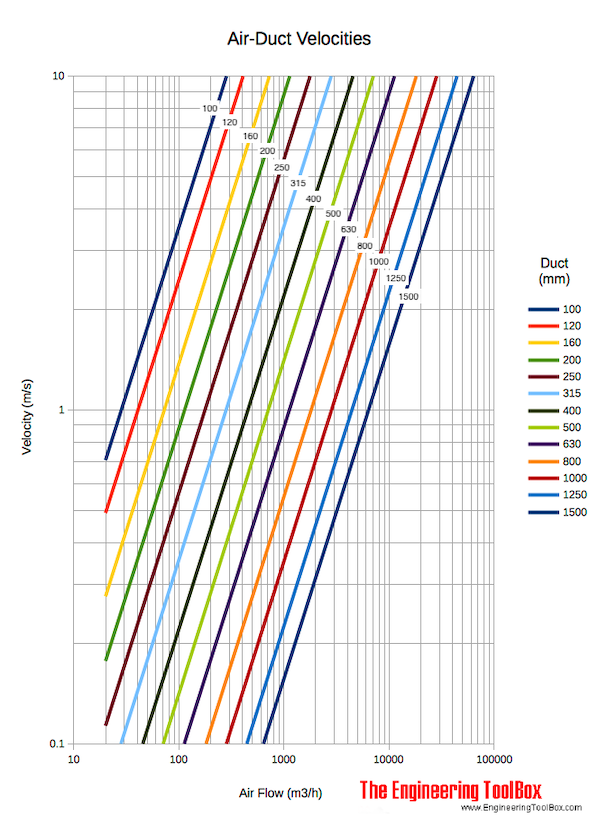

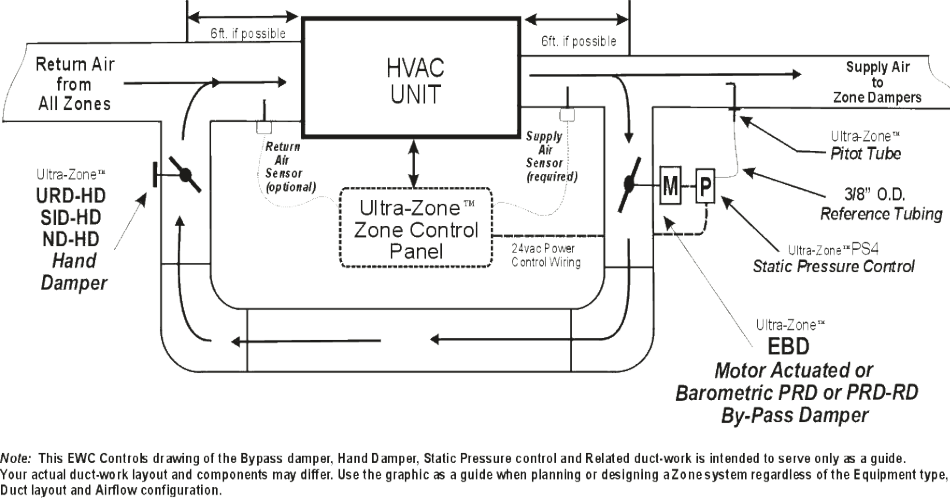

We pull many pounds of it into our lungs each day. In ductwork the law of conservation of mass means a duct size can be recalculated for a new air velocity using the simple equation. Remember statistically speaking the bottleneck on high static pressure systems is on the return side.

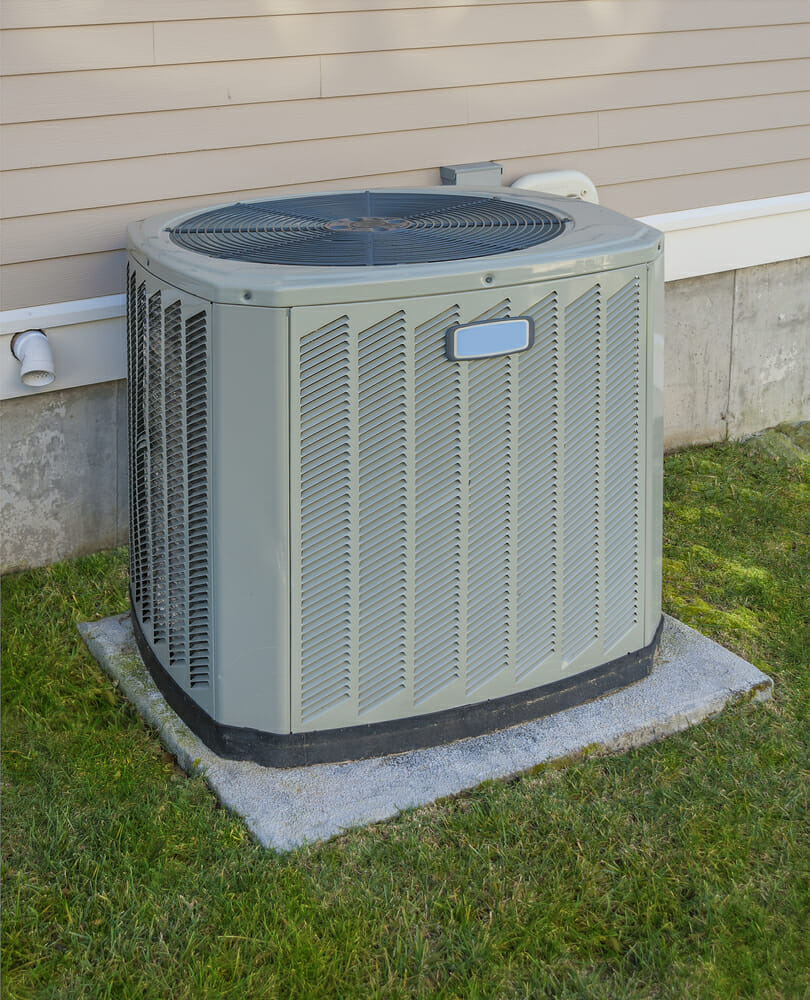

In most cases the air in a duct is assumed to be incompressible an assumption that overlooks the change of air density that occurs as a result of pressure loss and flow in the ductwork. Note also the return air grille sizing formula at the top of the chart. A typical air conditioner heat pump or furnace easily moves 20 tons of air a day.

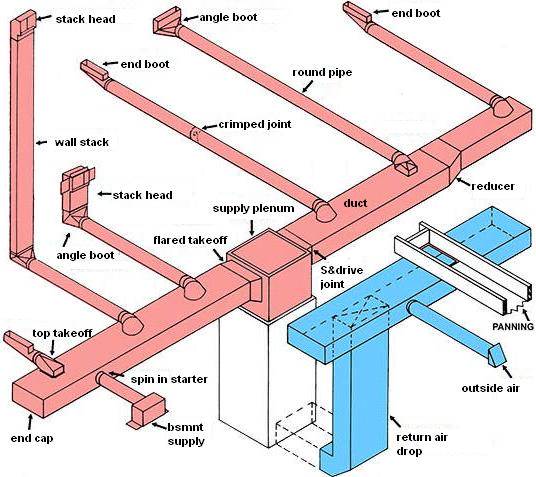

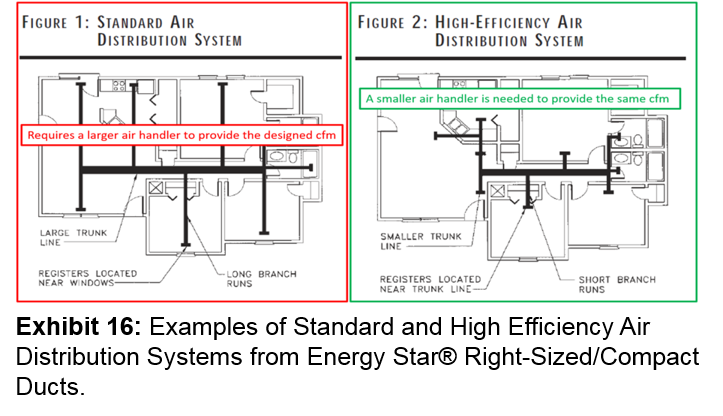

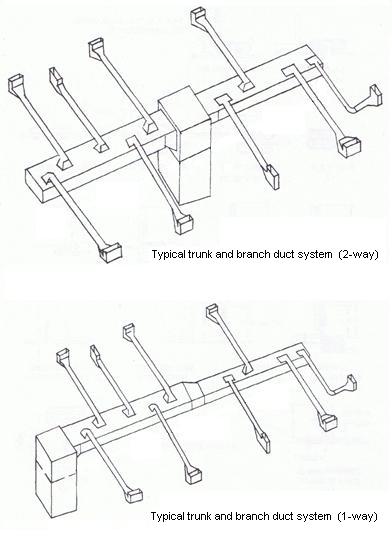

The less time the cool air is in the hot attic the less heat gain. Dampers on take off duct runs allow for adjustments of air distribution. Never locate ducts at the end of the trunk line run.

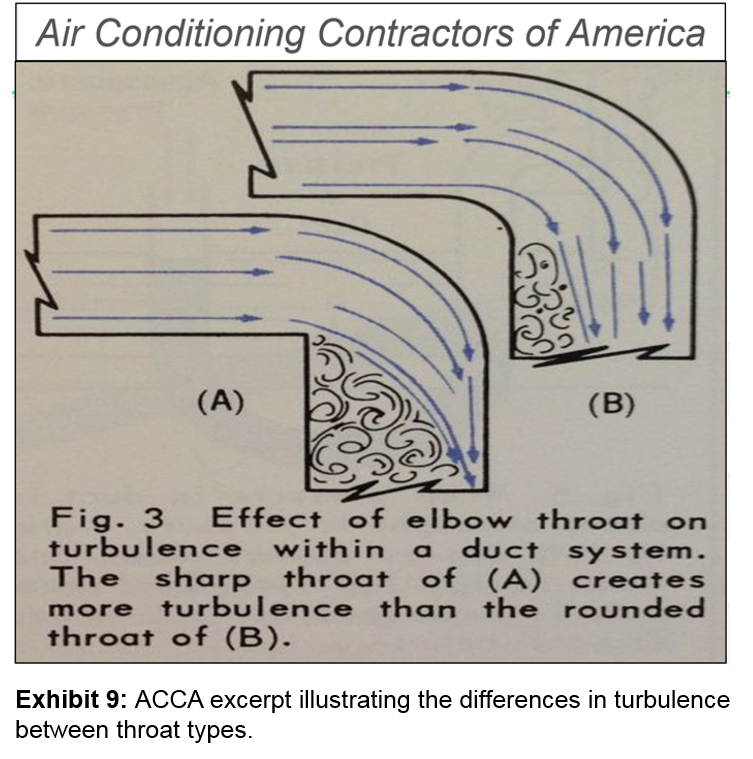

This can be caused by undersized returns long return duct lengths with bends or sound attenuating loops or a poor choice of air filtration. Now you have all the information you need to make an educated decision in purchasing your dust collector. Use the minimum length of flexible duct.

If no data is available use the generic flexible duct friction loss chart in acca manual d. We ll save that calculation for another. Use the air friction chart.

The 6 inch diameter duct area is 3 3 3 14 rad x rad x pi 28 3 sq inches which meets the need. Yes i m talking about 40 000 pounds. In order to maintain velocity reduce duct size.

However many modern residential air duct systems are constructed of fiber glass duct board or sheet metal ducts that are lined on the inside with fiber glass duct liner.